I. Desuperheating device consists of steam mixing pipeline (with nozzle), feed-regulating valve, throttle valve, stop valve, check valve, desuperheating water pipe, flange and standard components. The structure adopts Venturi tube nozzle. Main feature is that it has no transmission parts; desuperheating water boasts good atomization effect; nozzle is featured by convenient disassembly and assembly, as well as convenient repair.

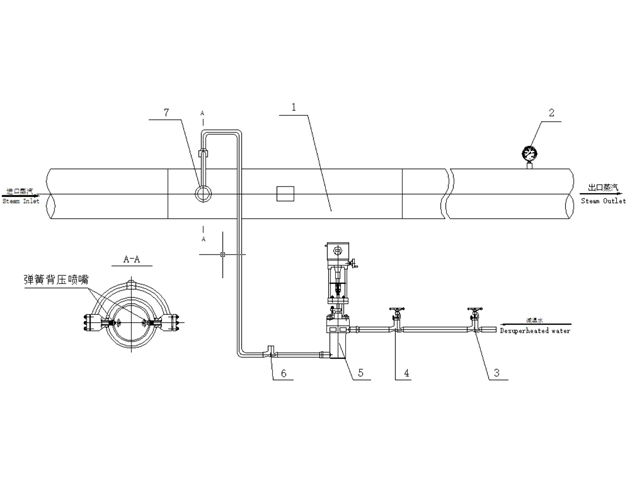

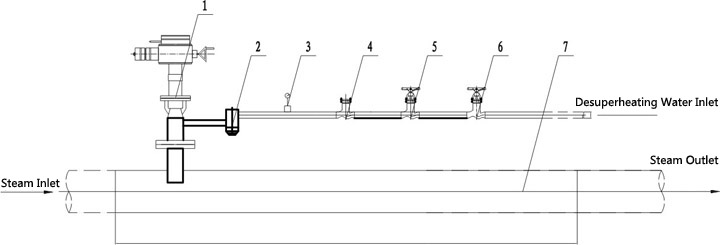

System Diagram of Desuperheating Devices

1. Mixing Pipeline

2. Thermometer

3. Stop Valve

4. Throttle Valve

5. Feed-regulating Valve

6. Check Valve

II. Desuperheating and Reducing Device with Spiral Nozzle

Structural Features:

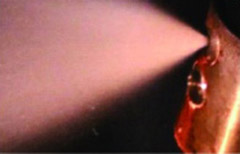

1. According to design mechanism, unique rotational flow structure makes desuperheating water realize high-speed rotational motion, obtains fine atomized water drops, and effectively avoids trickle-down effect. Adjustable ratio is 5:1.

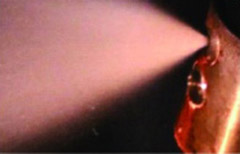

2. Good atomization effect. Through spiral nozzle, desuperheating water produces hollow taper, ring atomizing area and 51°-144° atomizing angle. Under wide-range impact and pressure load, it produces uniform mist spray with 0.1 mm liquid drops, greatly increases heat exchange area, and thus reduces atomization time and atomization section.

3. Spiral nozzle is inserted. Every well designed and manufactured spiral nozzle goes through flow coefficient test before installation, so as to ensure flow control accuracy.

4. Without driving elements and jamming, rotational flow structure owns large and smooth channel, which prevents nozzle from jamming.

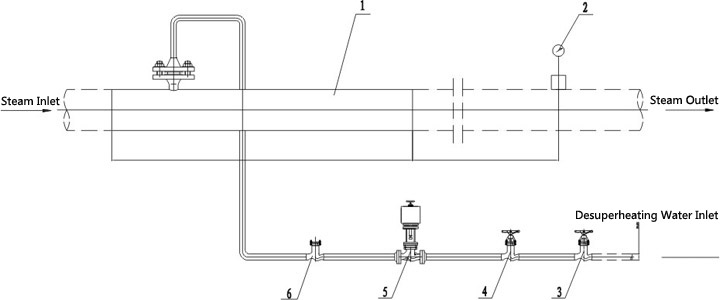

System Diagram of Desuperheating Device with Spiral Nozzle

1. Mixing Pipeline

2. Thermometer

3. Stop Valve

4. Throttle Valve

5. Feed-regulating Valve

6. Check Valve

III. Adjustable Atomizing Nozzle Desuperheater (Adjustable Nozzle Desuperheater)

When thermal load changes during actual use of steam desuperheater, injection area of traditional flute type desuperheater nozzle cannot be adjusted; injection flow can only be adjusted with desuperheating water regulating valve. When load changes lead to injection flow changes, injection speed of desuperheating water also changes. If injection speed is too low, atomization effect deteriorates, drain water increases greatly and even water attack occurs, which limit regulating capacity of thermal load.

Our adjustable atomizing nozzle steam desuperheater (adjustable nozzle desuperheater) changes injection area of desuperheating water, and thus changes injection flow of desuperheating water, rather than its injection speed. When load changes, desuperheating water always keeps the best injection speed to reach good atomization effect and avoid water attack, too much drain water and cavitation.

Since users’ on-site desuperheating water pressure is different, in order to ensure best injection speed of desuperheating water, the company adopts integrated mechanical structure of adjusting high differential pressure of desuperheating water and injection area of the nozzle. It is controlled by the same actuator, and adjusted instantaneously and synchronously.

By digesting and absorbing structural styles of world-famous brands (such as German HORA, American Yarway), this adjustable nozzle desuperheater is optimally designed by the company, tested by factory test bed and confirmed by users to be a stable, safe and reliable product as a substitute for imported products.

Advantages of adjustable atomizing nozzle desuperheater (adjustable nozzle desuperheater):

1) Increase regulation range of thermal load (5%-10%)

Adjustable nozzle desuperheater greatly increases regulation range of steam flow. Parameters are still stable and reliable after desuperheating under relatively low thermal load.

2) Improve product performance and enhance equipment service life

Adjustable nozzle desuperheater guarantees atomization effect of desuperheating water under all kinds of working conditions, without water attack, cavitation or accumulation of desuperheating water. With high steam dryness and only a little drain water, it reduces operation noise, eliminates pipeline vibration and enhances steam quality.

3) Simplify the system, reduce investment and save energy:

Adjustable nozzle desuperheater simplifies the whole desuperheating system. As a result, it realizes simple pipeline layout, less joints and safe operation. In particular, high differential pressure regulation is integrated with the nozzle, and a filter is installed at the inlet of desuperheating water, so desuperheating regulation is more sensitive without lag or jamming.

4) According to on-site installation conditions, it can be installed on horizontal or vertical steam pipelines.

|

|

|

10% Load

|

50% Load

|

100% Load (Bedstand Shot of Adjustable Atomizing Nozzle)

|

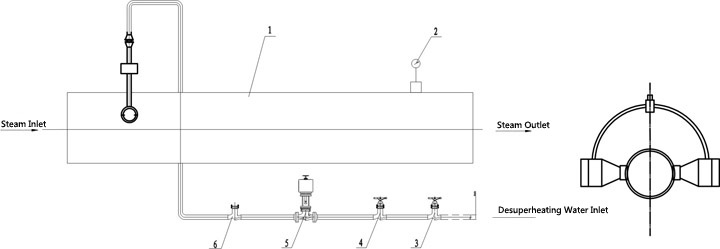

System Diagram of Adjustable Atomizing Nozzle Desuperheater

1. Adjustable Nozzle

2. Filter

3. Pressure Gauge

4. Check Valve

5. Throttle Valve

6. Stop Valve

Ordering Instruction:

Since this product is a non-standard product, please provide the following technological parameters when ordering goods. Indicate special conditions during negotiations:

1.Outlet Steam Flow Q; 2.Working Pressure of Steam; 3.Inlet Temperature of Steam T1; 4.Outlet Temperature of Steam T2; 5.Pressure of Desuperheating Water Pb; 6.Temperature of Desuperheating Water Tb; 7.Steam Pipeline Diameter ; 8. Actuator (Electrical/Pneumatic)

System Diagram of Pressure Reducing Device

1. Variable Frequency Reducing Valve

2. Mixing Pipeline

3. Spring Safety Valve

4. Pressure Gauge

5. Thermometer

Previous:

Is the home page

Next:

Is the end

搜派師(杭州)熱電科技有限公司

搜派師(杭州)熱電科技有限公司