- Home

- Company

- Products

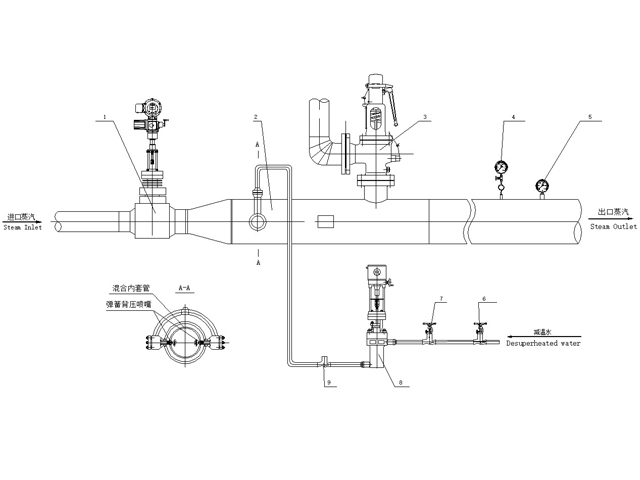

SURPASS Frequency conversion actuatorVariable Frequency Desuperheating and Reducing DeviceVariable Frequency Electric Regulating ValveVariable Frequency ValvePneumatic Regulating ValveUltrasonic Position (Level) MeterSeries Products of Throttling DevicePressure (Liquid Level) TransmitterTemperature Instrument SeriesFrequency conversion valve field caseComplete Automation Engineering Design

- Cooperation

- Culture

- Contacts

搜派師(杭州)熱電科技有限公司

搜派師(杭州)熱電科技有限公司